At present, biometric identification -- living fingerprint identification system is increasingly widely used. Veridicon's i-touch semiconductor fingerprint sensor is a low-power sensor with a 300 x 300 lattice and a resolution of 500DPI. The temperature sensor and resistance sensor are integrated internally, which can prevent electronic fraud.The sensor has the advantages of "small size, low cost, low power consumption, high security", and the chip surface is covered with a protective layer of pass-through protection, which can effectively prevent wear, corrosion, etc., so that many fingerprint identification system developers use.However, in the process of developing and using the i-touch fingerprint sensor, it is also found that the i-touch device is deficient in the efficiency of effective image capture, so some modifications are needed.

1. Confirmation of valid fingerprint images and existing problems

When the fingerprint image capture system is in operation, only the same image captured in two consecutive times can determine whether the image is a valid image.In actual use process, often is sensor launched the scanner first, and then checked and put finger scanned, so, at the beginning of may only be sweep to an incomplete fingerprint image, wait until the next scan, to get a complete fingerprint image, in this way, we get two different images, and thus must be scanned for a third time, but at the end of the third scan is not, who were due to stay too long on the sensor and cause impatient, may remove the fingers or moving again, this will make the final draw three image is different, so that the sensor will return an invalid image.The end result is a new fingerprint.

There are only two Settings for the working startup mode of the i-touch fingerprint sensor.The other is to start after the automatic continuous.The i-touch fingerprint sensor, on the other hand, does not have sensors that identify and control whether or not the subject is operating correctly.Therefore, both of the above two startup modes have the problem that the fingers of the examinee are not placed in place when they are started, resulting in empty scan or incomplete scan, resulting in invalid images, requiring multiple operations and affecting work efficiency.

Improved design for startup and synchronization

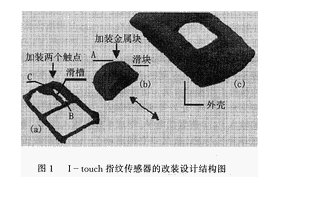

2.1 finger and digit touch switch

After careful study and repeated tests, the author added a finger in place switch in the i-touch fingerprint sensor, only when the finger is fully in place, the system starts to start the fingerprint scanning program, thus effectively solving the problem of out-of-sync between the work start and the finger in place.The specific structure is shown in figure 1. This design adds two contacts in the i-touch fingerprint sensor, one of which is extracted by the MCU P1.0 pin, and the other is directly connected to the ground.A metal block is added at point A of the slider to form A toggle switch.When working, make the finger under test push the slider from point B of the slider to point c. when fully in place, just connect the two contacts, and at the same time make the MCU input P1.0 pin set low level to form the MCU input signal. Through the interface between the MCU and PC, immediately start the i-touch fingerprint sensor to start fingerprint scanning.

2.2 switch hardware circuit

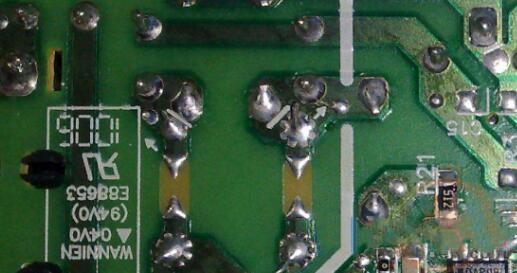

Figure 2 is the hardware circuit diagram of the interface design of single-chip microcomputer and PC in the toggle switch.This circuit USES ATML89C51, MAX232 and some peripheral components to form a serial communication circuit.

When the circuit is in operation, switch 1 is switched on and P1.0 pin changes from high level to low level. When the MCU detects that the P1.0 input terminal is at low level, it transmits "S" signal to the PC serial port through MAX232 to enable the PC to control the fingerprint sensor to execute the scanning program.When the PC wants to collect the fingerprint images, the com2 port sends the "E" signal to the microcontroller to indicate the end, and sets the P2.0 low level, at the same time makes the indicator light shine, indicating to the user that the fingerprint collection is completed.At this point, the user's finger can leave.

2.3 program design

The program block diagram is shown in figure 3. The single-chip program is written in C51 language. The block diagram is shown in figure 4.

This procedure USES Comport control, can be used to achieve the serial port communication based on WIN9X platform and MCU.

Procedure TMAINFORMA.Com Port11RxChar (Sender: Tobject;Count: Integer);

The Begin

ComPort11.ReadStr (Str, Count);

If the STR = 'S' then

Timer40. Enabled: = true;// perform fingerprint collection module

The End;

// output control module;

ComPort11.WriteStr (' E ');// output drive signal

Single-chip C51 program code is as follows:

H # include io51."

Void DELAY (unsigned int value)

{

While (value > 0) value--;

}

Bit FLAG0 = 0;

StaTIc const char TAB [] = "S";

The main ()

{

Char c = 0;

SCON = 0 x50;

TMOD = 0 x20;

TH1 = 0 xe6;

TR1 = 1;

While (1)

{

The do

{

If (RI= =1)

{

R1 = 0;

The P2 = ~ SBUF;

DELAY (3000);

The P2 = 0 XFF;

}

}

While (P1-0!= 0);

DELAY (2000);

SBUF=TAB [C];

While (TI!= 1);

TI = 0;

}

}

3 conclusion

This design has been successfully applied to the living fingerprint identification channel system and student fingerprint management system developed by zhanjiang normal university, with good results. Generally, the fingerprint set can be completed normally within 0.2 ~ 0.3 seconds of normal operation.It can obviously improve the effective fingerprint image acquisition rate.If it is used in the channel of fingerprint recognition, the effect is more obvious.

Inglês

Inglês  Chinês

Chinês  Alemão

Alemão  Coreano

Coreano  Japonês

Japonês  Farsi

Farsi  Portuguese

Portuguese  Russian

Russian  Espanhol

Espanhol